Last class, we were introduced to scissors mechanisms, one of the bases that revoluted Chuck Hoberman designs. Ive been playign around with those mechanisims and even make a wall clock with one of the circular ones! But I saw on this pset a chance to do something related with my research.

Here, at CBA, I am making some research on the legacy Ben Jennet left here. Ive been working with the metamaterials kit that was developed. As an introduction, CBA work has proposed since some student generations discrete structural cells. This digital materials allows to design not only shape of things but its own behaviour. Playing with different cells in a volumetric way will induce controlled anisotropies that will provide to the resultant lattice properties that cant be found on natural monolithic raw materials

Here I introduce to you the result of that work described. Is is shown 4 different faces (stiff, complient, auxetic and chiral). All faces can be assembled in cuboctahedrons and each cell can be assembled in the xy plane and in the z plane.

Not only they can be assembled members of the same family. The interesting properties comes here, by mixing faces with members of different families. Anisotropies can be controlled by mixing properly facets of the cell!

This anisotropy can be used to make what in this class are called transformable designs!. As an example, this covid I made this snake robot

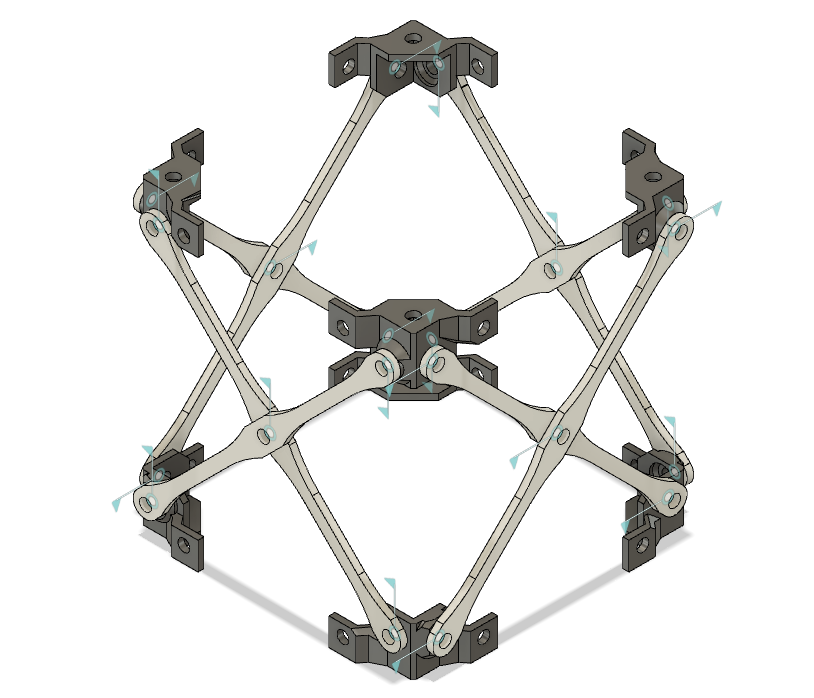

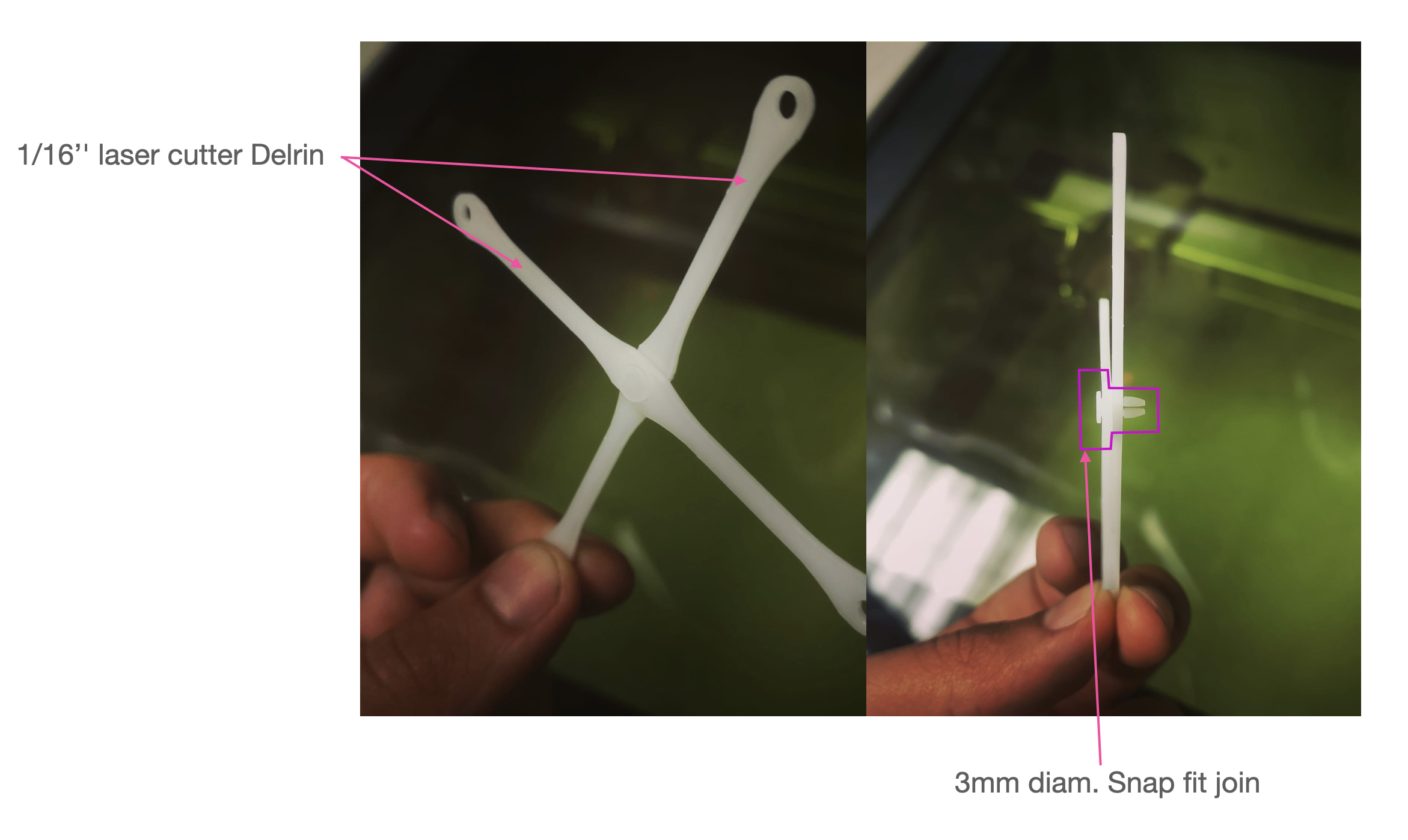

So I decided to start with the straight mechanisism. I designed this unit cell.

That will result in a zero poisson ratio (but as the chuck ball, I feel positive about controll that aswell) deformation:

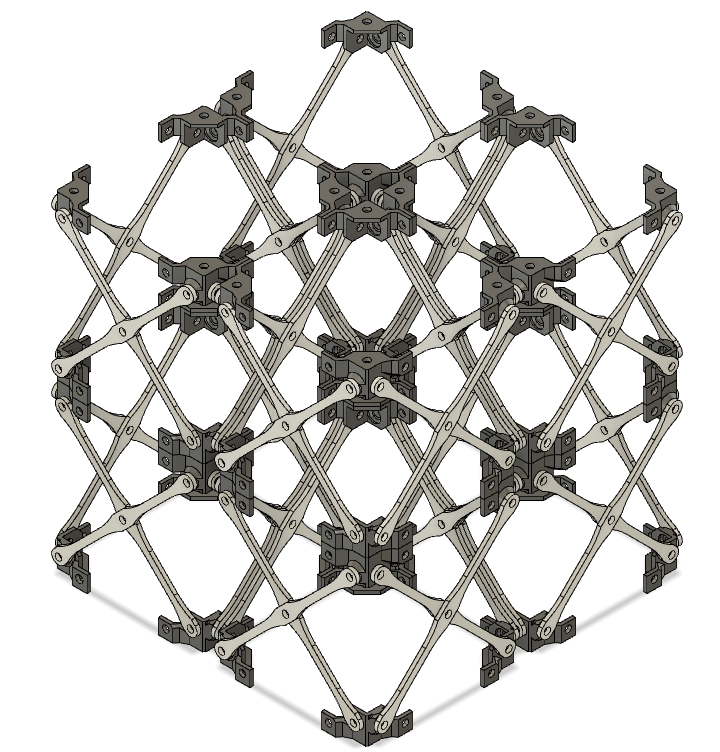

I tried to see which was the limit of Fusion 360 to simulate this cells and seems like its not happy with a 3by3 array. this is the limit of fluent simulation I could get.

As it can be seen. I made some features in the brackets that will allow to generate assemblies of this element that will be moved with only 1 DOF!

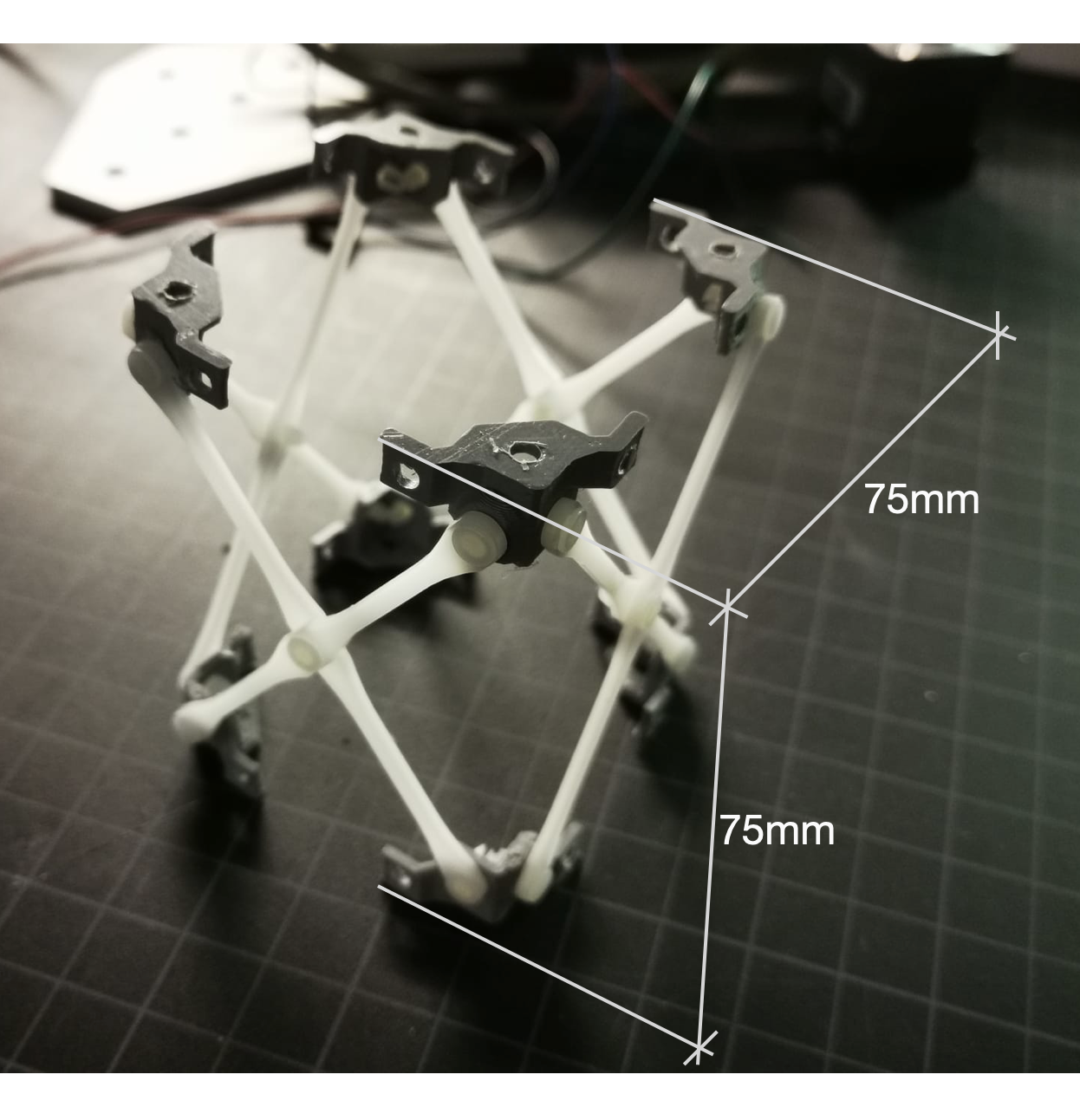

I made this elements in the same scale as the voxels, a 75 by 75mm cell.

I decided to manufacture a few of them. I lost lab access so the final mockup is way smaller I was thinking.

So here is the proof of the xy and z assembly capacity that this cell have and also that this pins allows reconfigurability but are strong enough to stands self weight loads capacity when actuated. Ive been playing with them a big part of the afternoon.

As part of the exercise, here are the motion of the x y assembled.

And here is the telescopic motion of the z assembly. Such a fun tower.

back to menu

back to menu