If you have questions related with this topic, please tag me at the issue tracker or send me an email at:

aprubio [at] mit.edu

If you have questions related with this topic, please tag me at the issue tracker or send me an email at:

aprubio [at] mit.edu

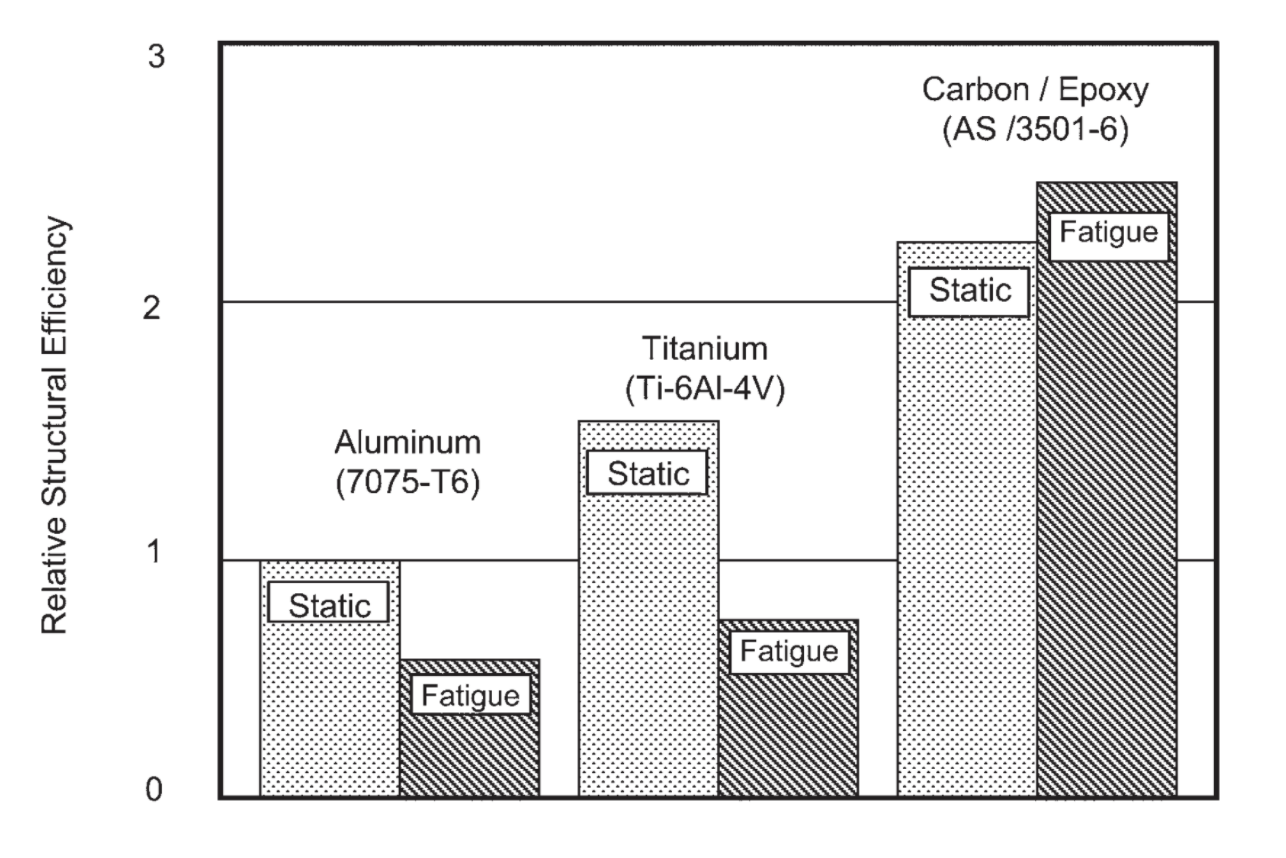

Combination of two or more materials that when combined, results in better properties than those individual components used alone.

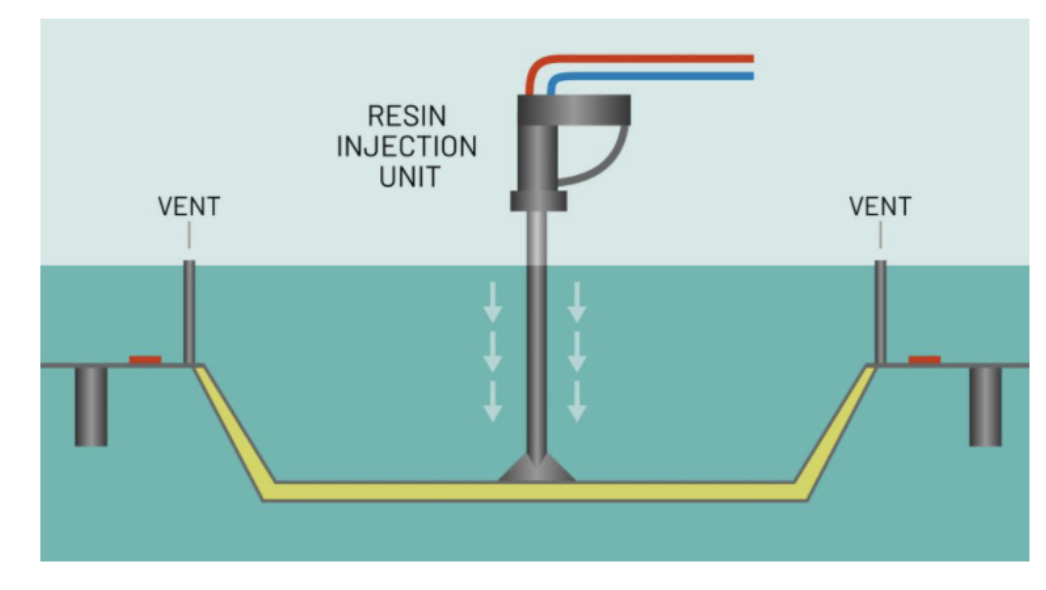

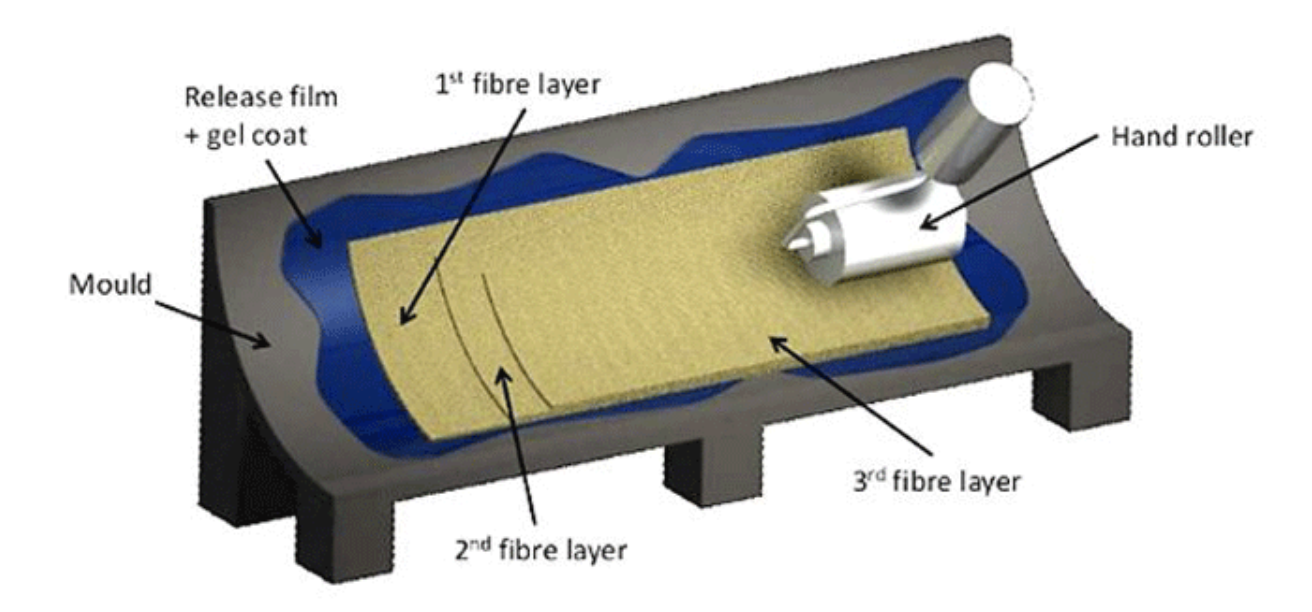

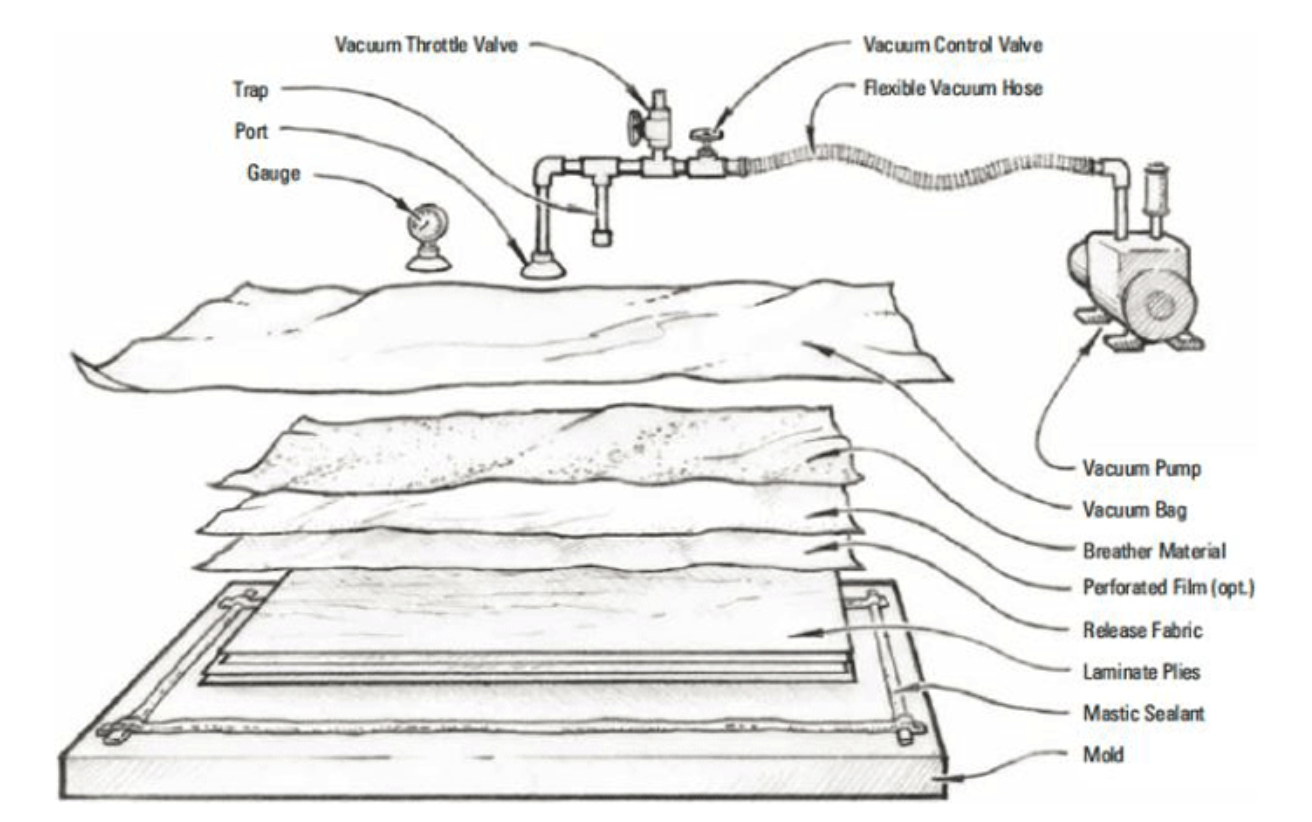

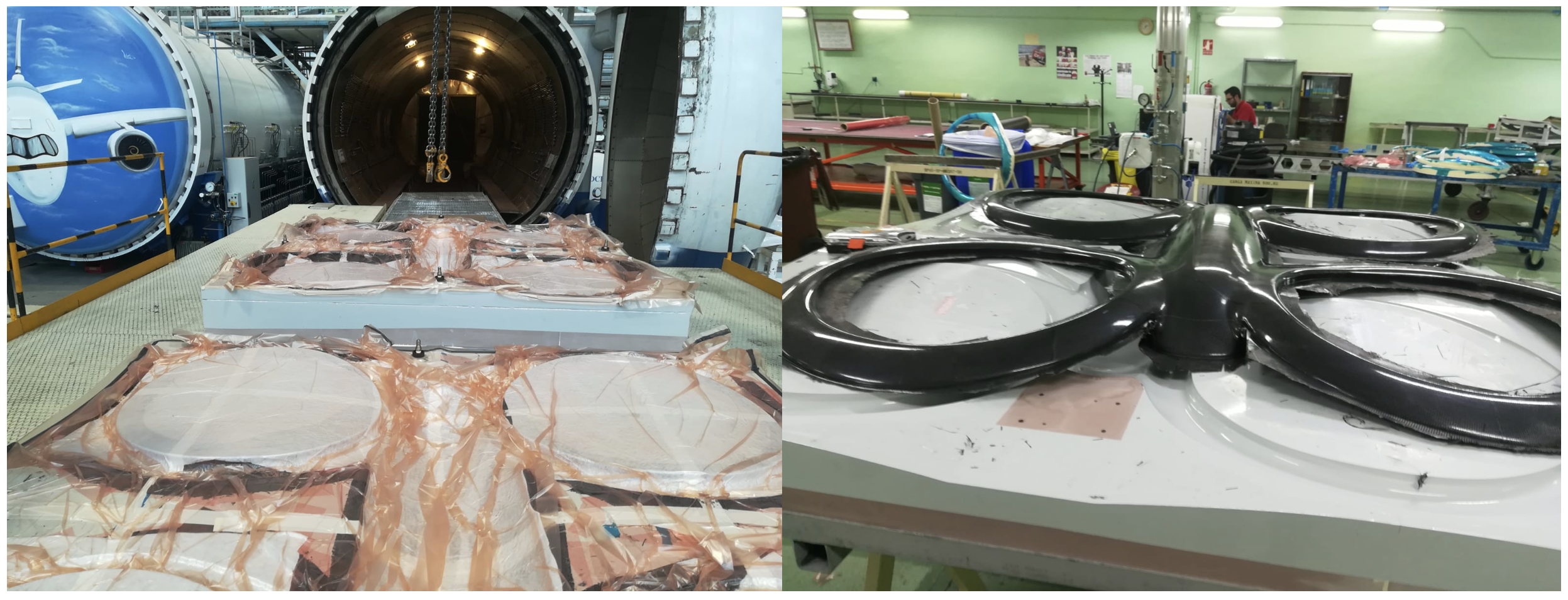

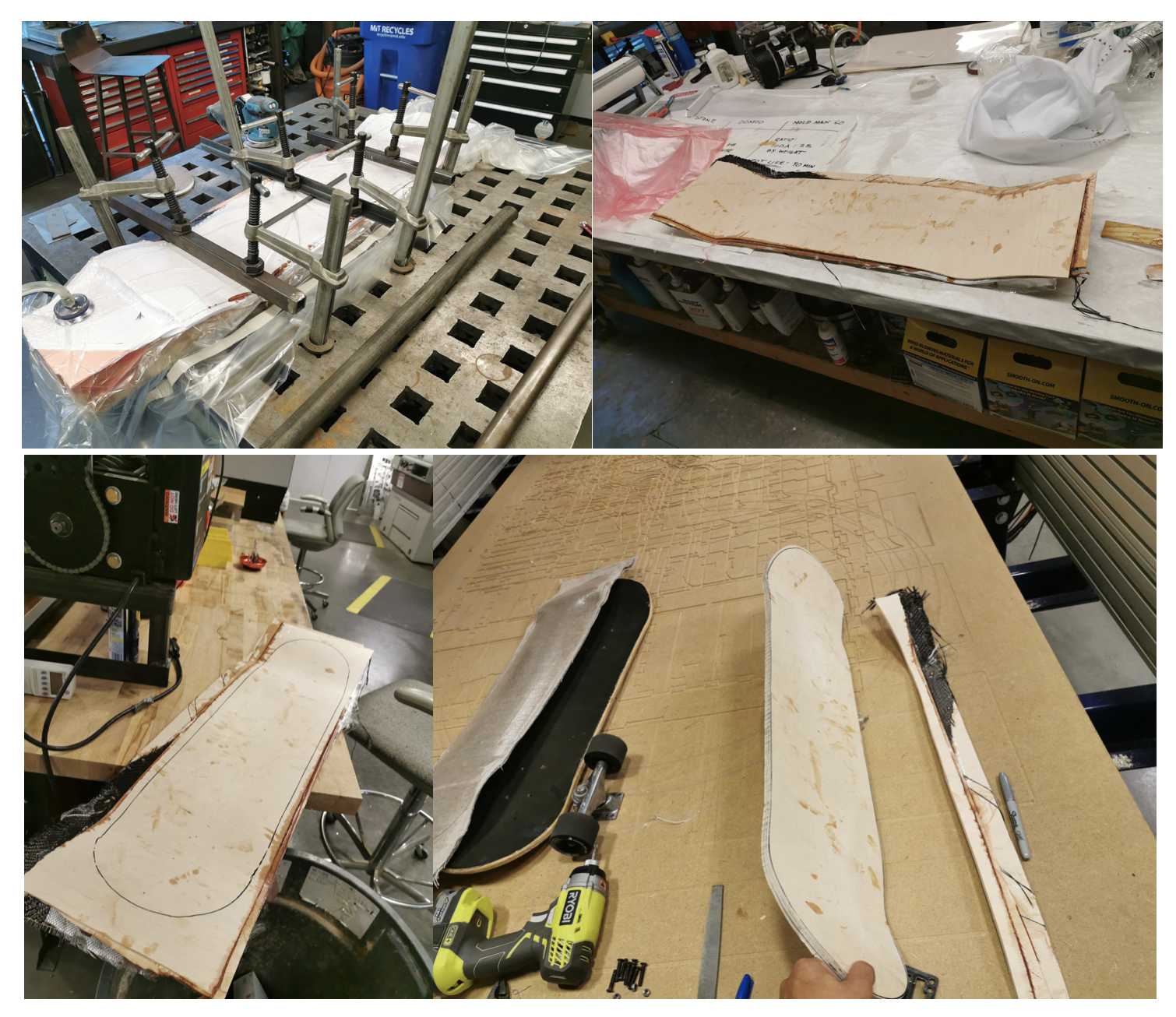

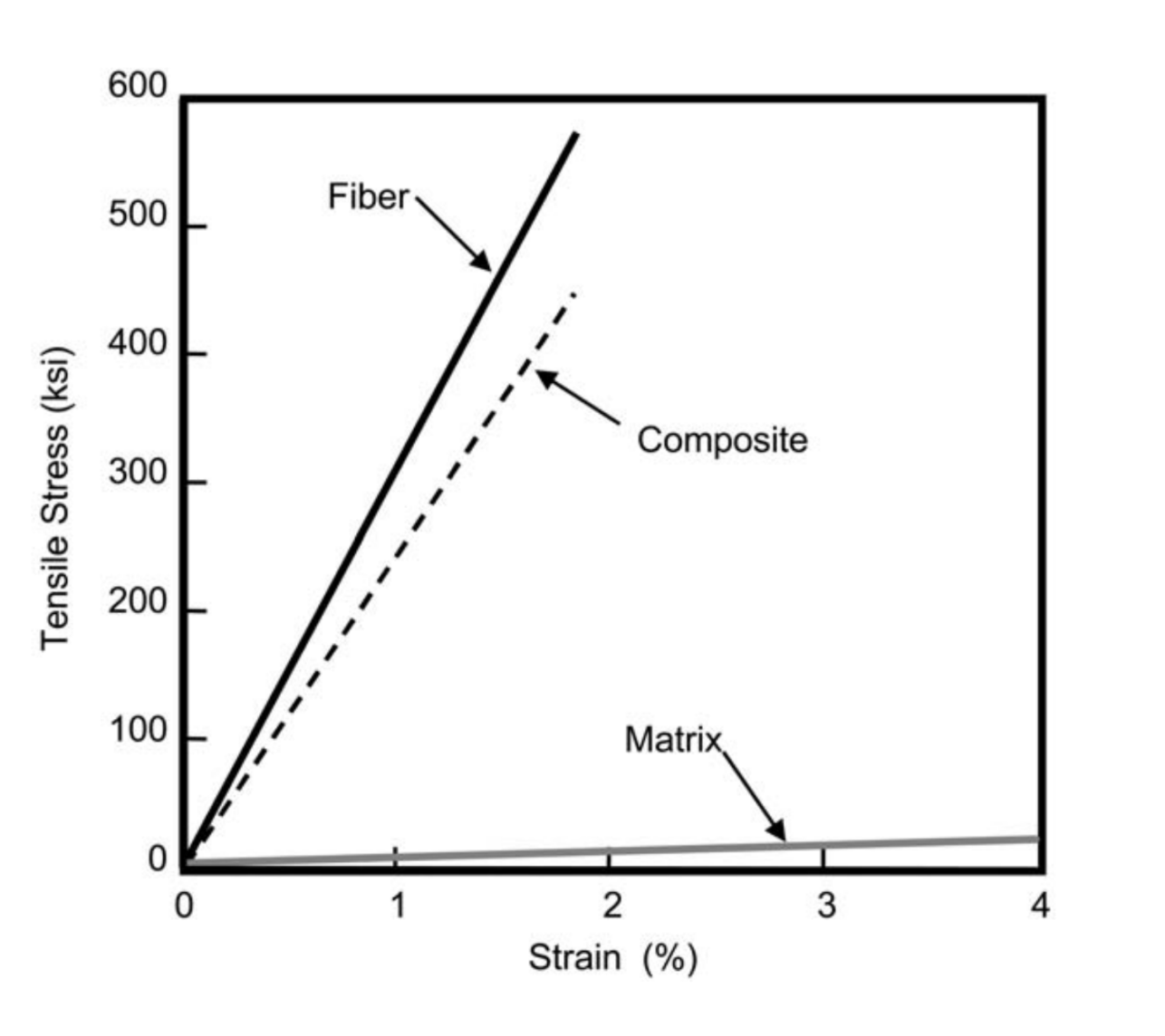

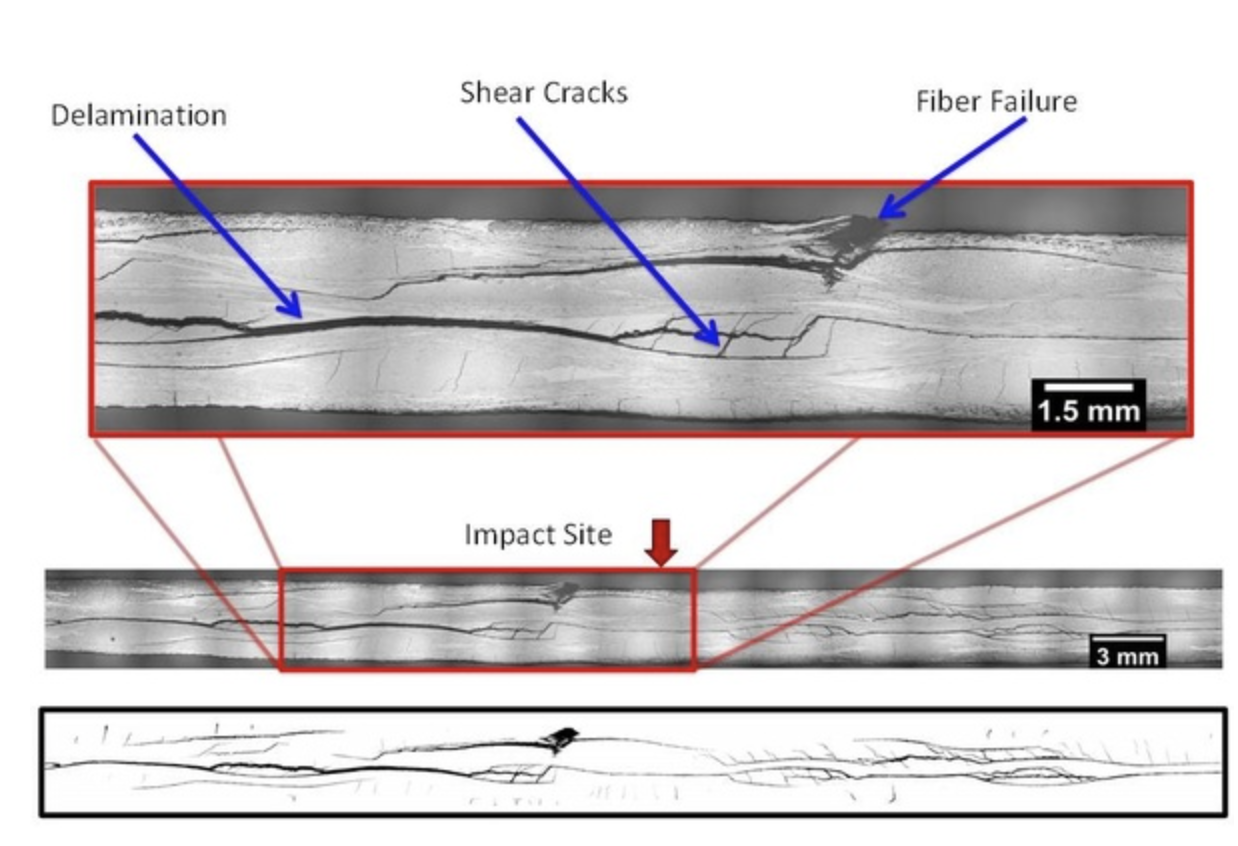

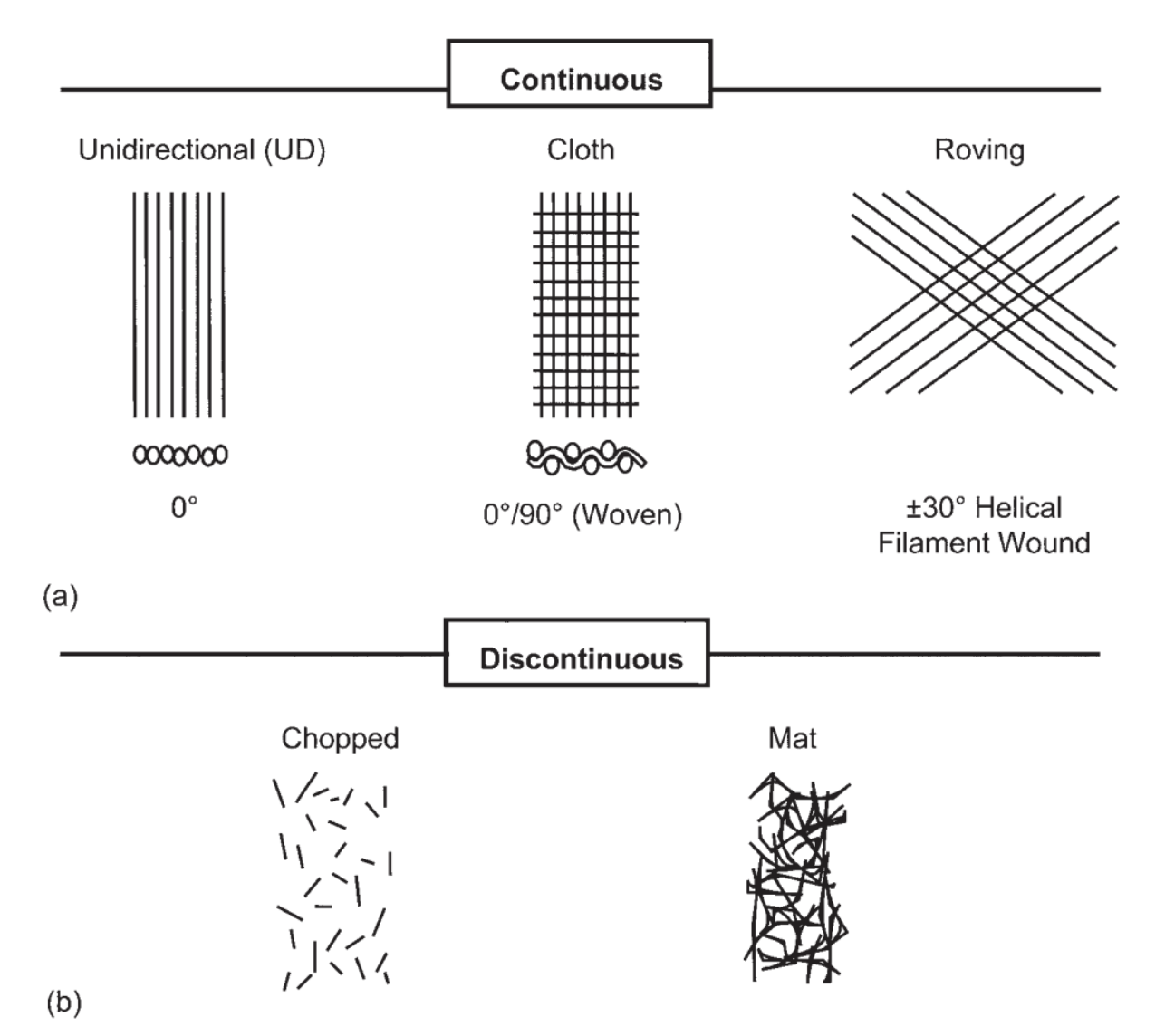

The concept of mixing two materials to sum up mechanical properties is pretty old! here is a fun link about the history of composite materialsThis two components are a reinforcement and a matrix. This process can get materials with greatly advantages compared with bulk monolithic materials. The main reason we infuse a resin into a fabric is because, independently, the fibers works great in tension but not at all in compression. And the resin works well (ish) in compression. When mixed, the resin distribute tensile loads into all layers of the lay up while the fibers, helps the resin to work great in compression.

THE SAME PRINCIPLE AS THIS CLASSIC VIDEO.

EXCEPT FOR GALVANIC CORROSION

But we also could use any other matrix, as bioplastics!

But we also could use any other matrix, as bioplastics!